TM 5-3990-264-13&P

0017

GENERAL WELDING MAINTENANCE - Continued

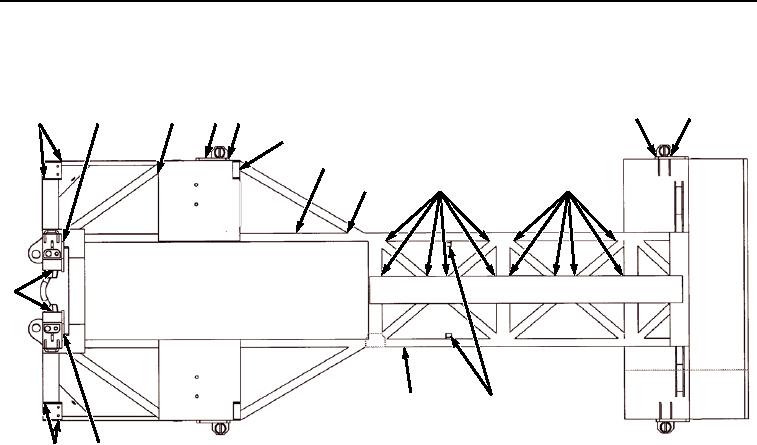

Weldment Points - Continued

7

7

3

1

4

7 7

4

5

4

4

4

2

5

6

3

1

Figure 1.

Top View

3.

CORNER FITTING AND ADJACENT STRUCTURE (Figure 1, Item 3). Due to the high loads that these fittings

can see in a transport mode, the crack should be repaired before reaching 1/2 inch (1 cm) in length. The

combined length of multiple cracks at any one location should not exceed 1/2 inch (1 cm). This applies to

cracks present in the adjoining structure also.

4.

CROSS MEMBERS (Figure 1, Item 4). These welds are located at the junction of the crossmember and the

main rails. A crack should be repaired before it has reached 2 inches (5.08 cm) at one location. The total length

of all cracks on a single crossmember should not exceed 2 inches (5.08 cm). When cracks are present on

several cross members, action should be taken to repair it at the next service. If a crossmember is completely

missing, repairs should be made prior to use.

5.

MAIN RAILS (Figure 1, Item 5). The main rails provide a major portion of the load carrying capacity of the IBC.

They support a portion of the load while loaded on the CBT and PLS trailer. Cracks in the main rail should be

repaired before reaching 1 inch (2.54 cm).

6.

LOCKING TABS (Figure 1, Item 6). The locking tabs are used to secure the IBC to the CBT and PLS trailer.

Due to the high loads that these tabs can see in the transport mode, a crack should be repaired before reaching

1/2 inch (1.27 cm) in length.

7.

STANCHION POCKETS (Figure 1, Item 7). The stanchion pockets are used to secure stanchion poles to IBC

during bridge erection boat retrieval. A crack should be repaired before it has reached 2 inches (5.08 cm). The

combined length of multiple cracks at any one location should not exceed 4 inches (10.16 cm).

03/15/2011Rel(1.8)root(maintwp)wpno(M06000)