TM 5-1940-321-13&P

NOTE:

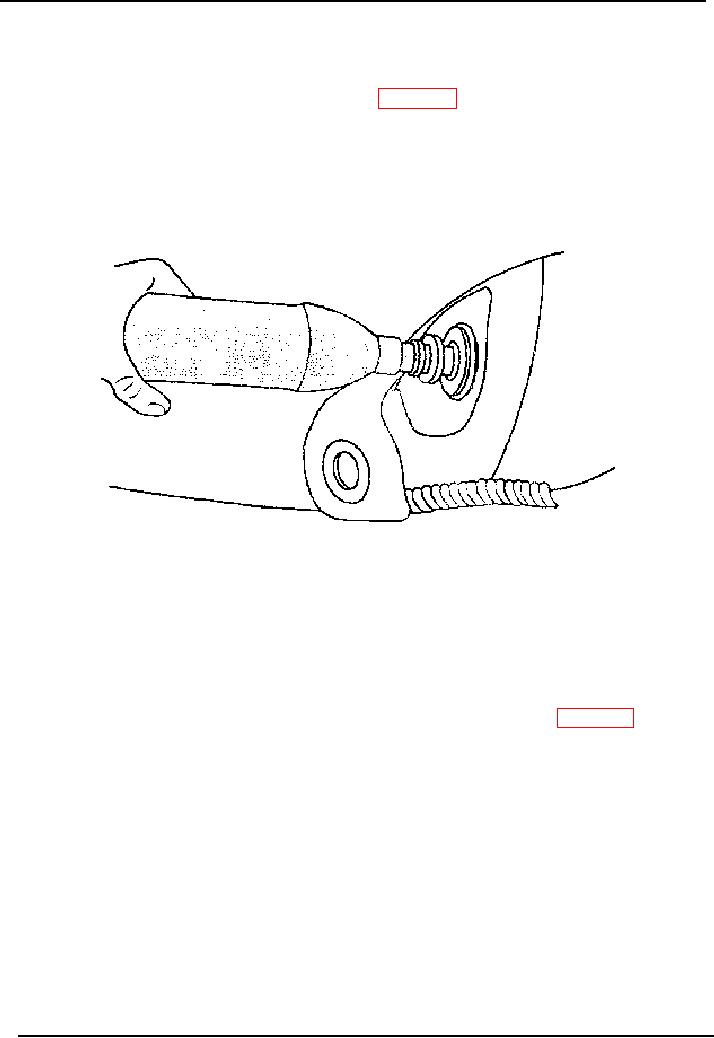

The valve regrinding operation is faster if an Electric drill or dremmel tool is used to

turn the male portion of the valve, as shown in figure 7-12. This requires a special

tool. The tool must be made by brazing a brass rod onto a metal valve insert. The

brass rod then must be installed in a drill or dremmel tool chuck. The metal valve

insert is screwed into the intercommunicating valve.

Figure 7-12. Using a Dremmel Tool to regrind Intercommunicating Valve.

( 11 ) A properly reground valve will have mating surfaces in complete and

continuous contact with each other. This condition is necessary for a complete

air seal. Proper mating of the surfaces is checked by first cleaning both male

and female portions of the valve. A grease pencil or chalk is used to trace two

parallel lines on the male portion of the valve as shown in figure 7-13. The lines

should be approximately 1/8-inch apart. Insert the male portion as far as it will

go into the valve body. Rotate the flywheel two complete turns. Remove the

male portion of valve for inspection. Where grease pencil or chalk lines are

undistributed, the two surfaces are not in contact and additional regrinding is

required. It the grease pencil lines are smudged or worn, the valve is properly

reground.

7-18