TM 5-1940-321-13&P

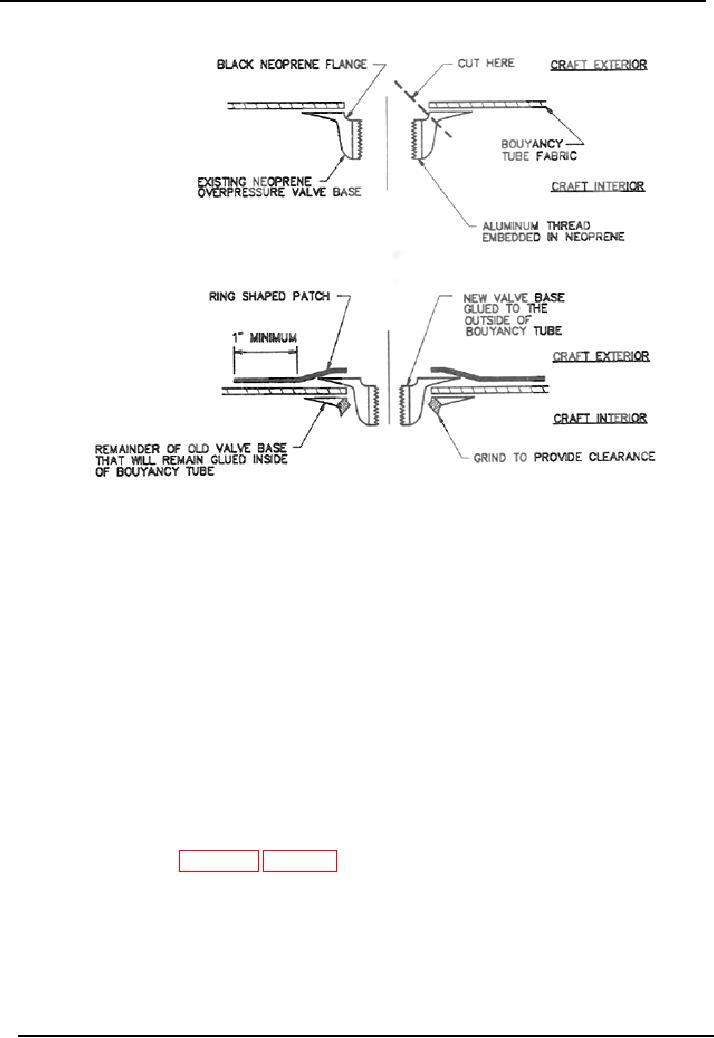

Installing an External Neoprene Valve Insert Base.

( 4 ) Using a dremmel tool and aluminum oxide stone, carefully smooth any rough

edges where the neoprene was cut inside the craft, and verify that any

protrusions are ground away.

( 5 ) Prepare to mount a new neoprene valve insert base on the outside of the

buoyancy tube. First center the new valve base in position over the hold and

then trace its outline using a silver pen. Using a dremmel tool, grind the inside

of the hole to increase its diameter approximately 1/8-inch. Trial fit the valve

base to verify that it fits easily into the hole.

( 6 ) Using a dremmel tool, lightly scuff the fabric within the traced circle. Also scuff

both flat surfaces of the valve base. Remove all dust.

( 7 ) Tape around the scuffed area on the buoyancy tube. Begin the glue schedule

(Appendix F, Table F- 1) using toluene solvent and neoprene glue.

( 8 ) Remove all tape and attach the valve base to the buoyancy tube. Bone it down

firmly using a boning knife.

7-39